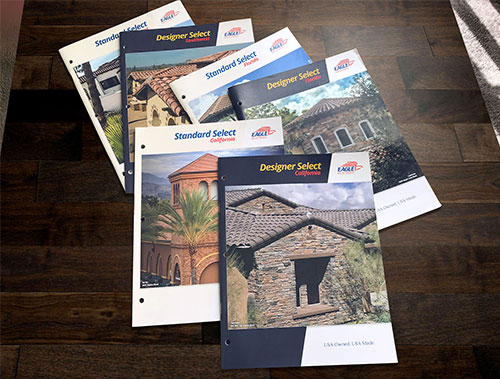

When the time comes to select a new roof for your next residential or commercial project, it is imperative to pick the best roofing material on the market. Ranking at the top of the totem pole, an Eagle concrete tile roof is more than just aesthetically pleasing to the eye; it lasts up to 75 […]