Weight = Long Lasting Protection That Stands The Test Of Time

In order to produce an unrivaled, enduring product, Eagle Roofing Products sources the best raw materials to manufacture our concrete roof tile. Consisting of sand, cement, water and oxide (pigment), this mixture is pressed or extruded into aluminum or steel molds to create the shape of the concrete tile and then it is sent into a kiln. The extrusion process typically utilizes over 3,000 lbs. of pressure, per square, in order to ensure the strength, weathertightness and long-term durability of the tiles. At Eagle, we voice that “our weight is our strength.”

These natural ingredients make concrete roof tile dense and heavy, resulting in an extremely durable product that is able to withstand the harshest of weather and is longer-lasting than traditional roofing materials, like asphalt shingles. In addition, its high thermal mass provides an added benefit by absorbing and storing heat (like a sponge) during the day and releasing it slowly into the structure at night. Thereby, keeping your residential or commercial building cooler during the day in the summer and warmer at night in the winter; helping reduce heating and cooling costs. The results are unmatched longevity, thermal superiority and exceptional weather and impact resistance ratings.

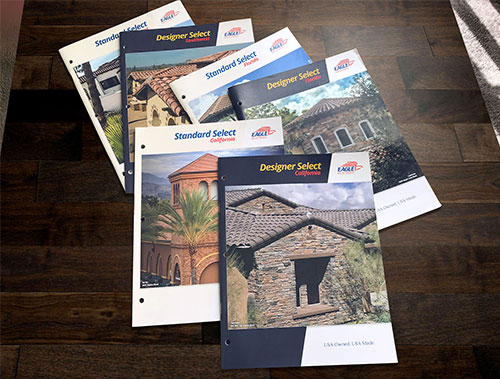

Concrete roof tiles provide the beauty to meet any architectural demand, the strength to withstand all weather conditions and the durability to stand the test of time. They also provide the perfect platform for the future of energy efficiency.

For more information about the features and benefits of concrete roof tile, view our video.